Author: Tyler Mashek

Vacuum technology stands as one of the most transformative innovations in human history, quietly powering everything from light bulbs to semiconductor manufacturing. Understanding how vacuum pumps evolved from simple mechanical devices to sophisticated precision instruments reveals the fascinating interplay between scientific discovery and technological advancement. This comprehensive exploration traces the history and evolution of vacuum pump technology and examines how these machines continue to shape our modern world.

Ancient philosophers debated whether nature truly “abhors a vacuum,” but practical vacuum creation remained elusive for millennia. Early attempts relied on simple displacement methods, such as inverting water-filled containers or using primitive suction devices. These rudimentary techniques could only achieve partial vacuums and provided limited practical applications.

The first documented vacuum experiments occurred in ancient Greece, where Hero of Alexandria described basic pneumatic principles around 60 AD. However, these early devices functioned more as curiosities than practical tools, lacking the mechanical sophistication needed for sustained vacuum production.

The 17th century marked a revolutionary period for vacuum science, beginning with Evangelista Torricelli's groundbreaking barometer experiment in 1643. Torricelli demonstrated that atmospheric pressure could support a column of mercury approximately 30 inches high, proving the existence of atmospheric pressure and creating the first artificial vacuum space.

Otto von Guericke advanced vacuum technology significantly with his invention of the first mechanical vacuum pump around 1650. His famous Magdeburg hemispheres demonstration showcased the tremendous force of atmospheric pressure, requiring multiple horses to separate two hemispheres after air removal. Guericke's pump utilized a piston-cylinder arrangement with leather seals, establishing the fundamental principles still used in modern reciprocating vacuum pumps.

Robert Boyle further refined Guericke's design, creating more efficient pumps for scientific experiments. Boyle's improved vacuum chamber allowed systematic studies of air pressure relationships, leading to the formulation of Boyle's Law and advancing our understanding of gas behavior under reduced pressure conditions.

The Industrial Revolution brought significant mechanical improvements to vacuum pump design. Steam engines provided reliable power sources for larger vacuum systems, enabling industrial applications previously impossible with manual operation.

Manufacturing processes began incorporating vacuum technology for various purposes:

These industrial applications demanded more robust and reliable vacuum pumps, driving innovations in materials, sealing methods, and mechanical design principles.

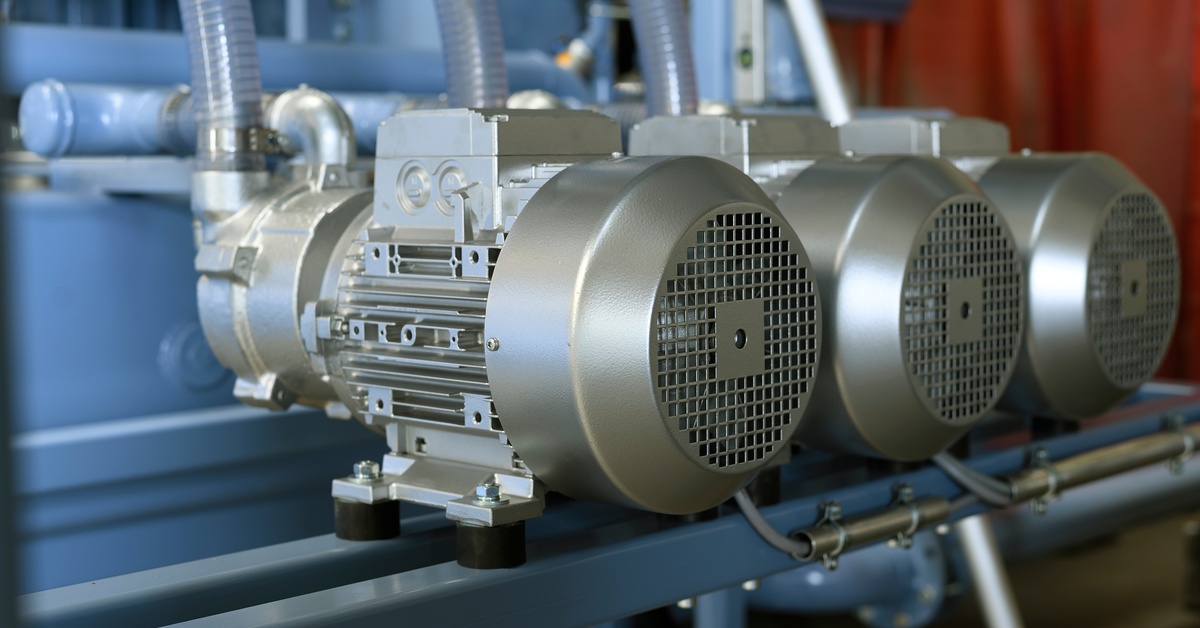

The advent of electrical power in the late 19th century revolutionized vacuum pump capabilities. Electric motors provided consistent, controllable power sources that enabled continuous operation and precise speed regulation. This development led to the creation of rotary vacuum pumps, which offered several advantages over reciprocating designs.

Rotary pumps eliminated the pulsating action inherent in piston-based systems, providing smoother vacuum generation. The continuous rotation allowed higher pumping speeds and more consistent vacuum levels, making them ideal for applications requiring steady-state conditions.

The earliest sewage trucks were simple horse-drawn carriages with barrels made to collect waste. The first motorized vacuum sewage truck wasn’t introduced until the early 20th century. This truck utilized vacuum power to suck up liquid waste from pipes underground.

The electronics industry's emergence in the early 20th century created unprecedented demand for high-quality vacuum technology. Radio tubes, television cathode-ray tubes, and early electronic devices required extremely pure vacuums to function properly.

Vacuum tube manufacturing demanded precise control over internal atmospheres. Even trace amounts of residual gases could cause tube failure or performance degradation. This requirement drove development of more sophisticated pumping systems capable of achieving and maintaining ultra-high vacuum conditions.

World War II created urgent military needs that accelerated vacuum technology development. Radar systems, communication equipment, and electronic warfare devices all relied heavily on vacuum tube technology. Military specifications required more reliable and efficient vacuum pumps capable of operating under challenging conditions.

The Manhattan Project also utilized advanced vacuum technology for uranium enrichment processes. These applications demanded vacuum systems with unprecedented reliability and performance specifications, pushing the boundaries of existing technology and spurring rapid innovation.

The 1940s and 1950s witnessed several crucial breakthroughs in vacuum pump technology. Diffusion pumps, utilizing heated mercury vapor to achieve ultra-high vacuums, became standard equipment in research laboratories and industrial facilities.

Turbomolecular pumps emerged as game-changing technology, utilizing high-speed rotating turbine blades to compress and evacuate gas molecules. These pumps could achieve extremely low pressures while maintaining oil-free operation, making them ideal for applications requiring contamination-free environments.

Hydrovac trucks also started to appear around the mid-20th century. In the 1970s, these specialized trucks were created to streamline excavating projects, later developing into its own specialized industry.

The semiconductor industry's rapid growth during the 1960s and beyond created entirely new categories of vacuum requirements. Integrated circuit manufacturing processes demanded ultra-clean, ultra-high vacuum environments to prevent contamination during delicate fabrication steps.

Semiconductor processing introduced concepts such as load-lock systems, allowing materials to enter vacuum chambers without compromising the main processing environment. These systems required sophisticated vacuum pumps with rapid pump-down capabilities and precise pressure control.

Contemporary vacuum technology serves an enormous range of applications across multiple industries. Scientific research facilities utilize vacuum systems for particle accelerators, space simulation chambers, and materials research. Medical applications include vacuum-assisted surgical procedures and pharmaceutical manufacturing processes.

Modern vacuum pumps demonstrate remarkable diversity in design and capability:

Emerging technologies continue expanding vacuum pump applications and capabilities. Quantum computing requires ultra-high vacuum environments with exceptional stability and cleanliness. Space exploration demands lightweight, reliable vacuum systems for planetary surface operations and spacecraft manufacturing.

The history and evolution of vacuum pumps represents a remarkable journey from simple mechanical curiosities to sophisticated precision instruments essential for modern technology. From Torricelli's first barometer to today's smart, connected systems, vacuum technology continues advancing to meet increasingly demanding applications.

Understanding this evolution provides valuable perspective on how fundamental scientific principles transform into practical technologies that shape our world. As new applications emerge in quantum computing, space exploration, and nanotechnology, vacuum pump technology will undoubtedly continue evolving to meet these challenges and enable future innovations.