Author: Tyler Mashek

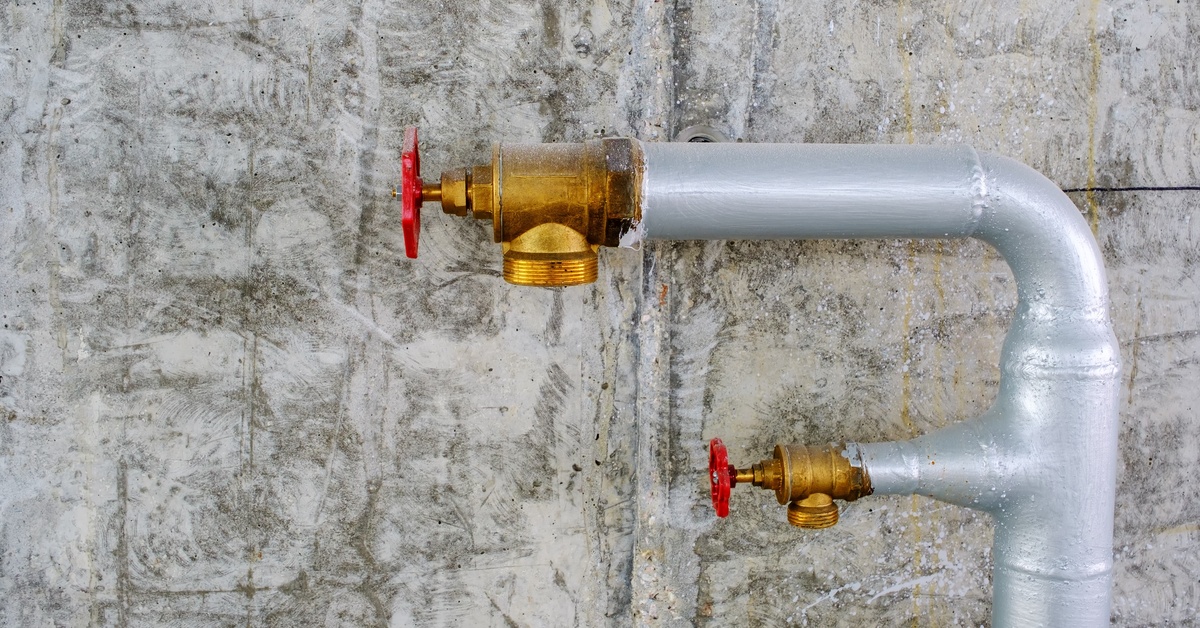

For those involved in fluid control systems, brass valves are essential for maintaining efficiency, reliability, and durability. These components play a crucial role across a wide range of industries, delivering exceptional performance even in high-pressure and high-temperature environments.

Keep reading as we explore what you should know about using brass valves, including their key features, to help you make the most of their capabilities.

One of the key benefits of brass valves is their exceptional resistance to corrosion. Brass is an alloy of copper and zinc, and it’s naturally resistant to water-induced oxidation. This trait makes these valves a dependable choice for systems that handle water or other fluids. When compared to iron and steel, brass significantly reduces the risks of leaks and mechanical failures caused by corrosion.

For instance, the inherent properties of brass allow these valves to maintain their structural integrity when used in plumbing or on vacuum trucks over extended periods. This durability minimizes potential downtime due to repairs and ensures long-term reliability.

Brass valves are engineered to provide tight seals that prevent leaks. Whether they’re used in residential plumbing, industrial manufacturing, or on vacuum trucks, the precision and craftsmanship behind brass valves ensure system efficacy.

From ball valves that utilize a spherical sealing mechanism to gate valves designed for on-and-off control, each type excels in its ability to prevent leakage even under high-pressure conditions.

The versatility of brass valves makes them suitable for a broad array of applications. Some of the industries that use these valves include the following:

Their adaptability stems from the ability to withstand extreme temperatures and pressure while maintaining reliable performance. Whether they’re managing slurry, water, sludge, gas, septage, or oil, brass valves deliver consistent flow control.

Brass valves are capable of handling high-pressure applications without compromising their performance. For example, in vacuum operations, where tanks operate under negative pressure, brass valves play a critical role by opening the flow of air into the vacuum tank. While brass valves are often associated with high-pressure plumbing applications, their durability and reliability make them essential for maintaining functionality in vacuum systems as well.

Brass valves feature a robust design with reinforced components that utilize durable materials and advanced coatings. This extends their lifespan and reduces maintenance costs, making them a cost-effective choice for long-term use.

The design of brass valves is centered around user convenience and ease of operation, making them a reliable choice for a variety of applications. Many brass valve types, such as lever and ball valves, are designed for simple, manual operation through intuitive mechanisms that anyone can use with minimal training or effort. Some piston valves offer configurations that accommodate electric, hydraulic, or pneumatic operation. This versatility simplifies fluid system management while reducing the risk of user errors.

By streamlining operations, brass valves enhance reliability and overall system performance, making them a critical component on any vacuum truck or stationary plumbing setup. Their durable, user-friendly design ensures efficiency in even the most demanding environments.

The inherent strength of brass contributes to the longevity of these valves. Unlike more brittle materials, brass exhibits a natural flexibility that prevents cracks and fractures under mechanical stress. This durability ensures consistent performance, even in demanding conditions where other materials might fail.

For instance, factories and construction sites often rely on brass valves to endure heavy operational loads. Their ability to resist wear and tear makes them a preferred choice in environments that require dependable equipment.

Brass valves are available in various configurations to suit specific operational requirements:

These options allow users to select a valve design tailored to their specific needs, maximizing system efficiency and functionality.

Brass valves require consistent maintenance to ensure optimal performance and prevent potential system issues. When it comes to repairs, it’s important to have the right tools on hand such as wrenches, sealant tape, and replacement seals. Specific repair instructions can often be found in the valve’s user manual or through manufacturer resources online, which provide step-by-step guidance tailored to the valve model.

For brass valves specifically, consider the material’s properties. Brass is resistant to corrosion but can be susceptible to dezincification in environments with high levels of chlorides or ammonia. To maintain longevity, avoid exposing brass valves to highly acidic or alkaline conditions, and ensure the use of compatible lubricants and sealants designed for brass components.

Regular cleaning to remove debris and using filtration systems to minimize particle buildup can also go a long way in preserving the valve’s integrity.

When you’re looking to optimize your fluid control systems, brass valves provide an invaluable solution. With durability and precision engineering, these valves facilitate efficient system management across multiple industries. Their adaptability, ease of maintenance, and ability to handle extreme conditions position brass valves as essential components in modern fluid systems.

Proper installation of brass valves is key to their performance, durability, and system efficiency. Correct installation prevents leaks, reduced functionality, and system damage. Choosing the right valve type and size, ensuring compatibility with pressure and temperature, and maintaining clean, debris-free connections are all essential to keep your systems working optimally.

Using the right tools and sealants ensures a tight seal, while testing the valve after installation confirms it works properly. Proper installation results in a system that stays efficient and trouble-free for years.

By understanding what you should know about using brass valves, you can ensure that you can select and implement the ideal solution for your fluid control needs. Whether you’re improving a plumbing system or increasing efficiency, brass valves deliver reliability and high performance.